Build quality DIY woodworking projects with our in-depth guides, tips, techniques, reviews and construction plans.

Whether you are a hobbyist, student, engineer, artisan or anyone else interested in woodworking, you will find valuable information here.

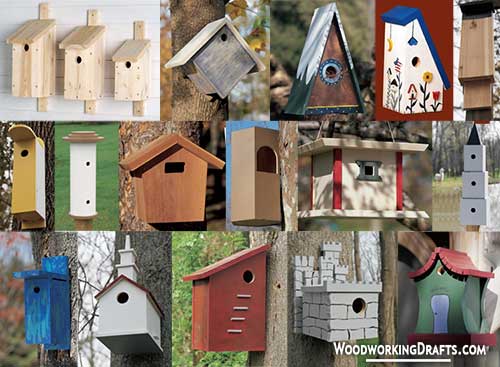

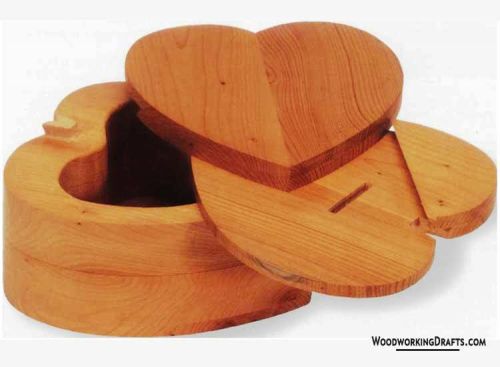

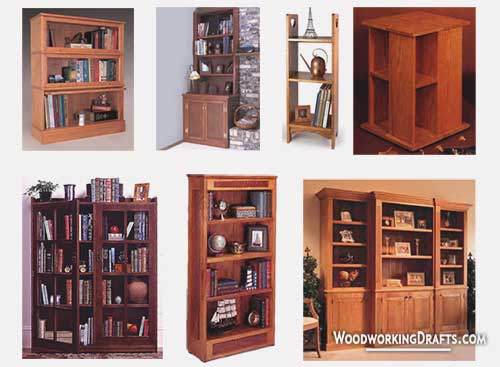

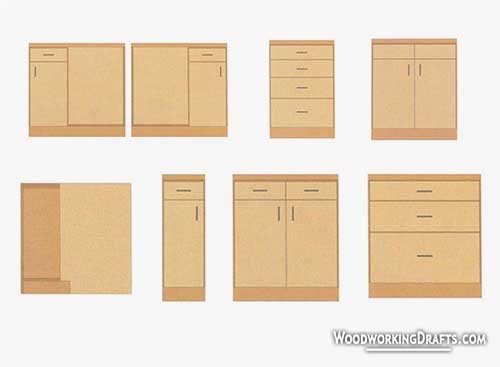

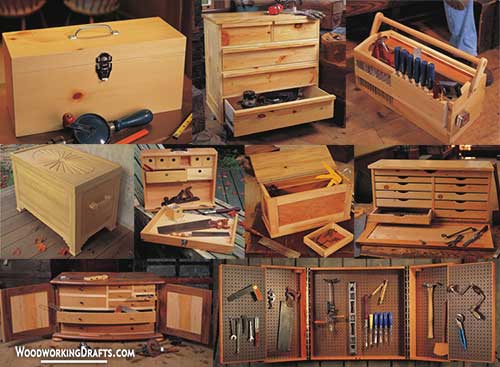

Popular Woodworking Plans

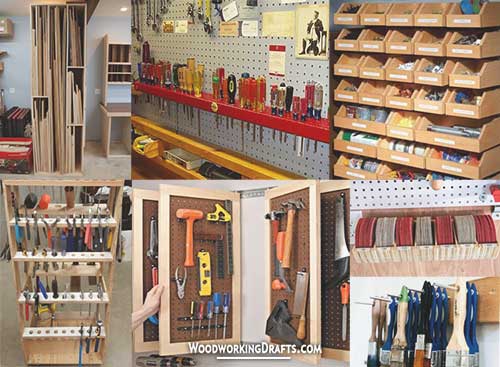

Top Woodworking Guides

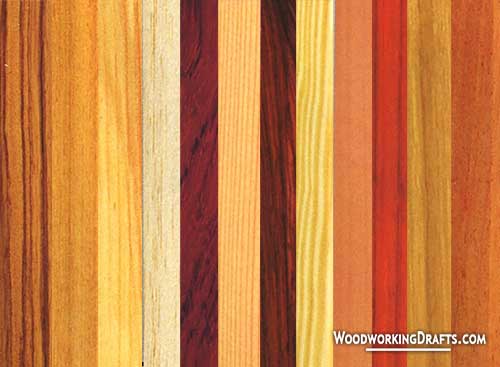

12 High Quality Woods For Woodworking At Affordable Prices

Quality woods for woodworking like white oak, walnut and cherry can be quite expensive, especially in certain regions. Purchasing local timber in your area will always give you the best prices.

Here are some economic lumber alternatives that help you build sturdy and beautiful DIY projects while keeping costs low.

Yellow Birch

Yellow birch can be a bit brittle and challenging to cut, but it’s widely used in crafting kitchen cabinets. It is usually available at most lumber stores.

Sassafras

Sassafras has a distinct tangy odor and unique grain patterns. It is a durable hardwood that is open-pored and soft to work with.

It has a color similar to chestnut and can be used as a replacement for it.

It can be used both as the primary timber in your project or as a secondary wood for contrast.

Eastern White Pine

Easter white pine is easy to cut and plane and leaves a beautiful finish. Sometimes you may encounter knots or pockets, but you can easily cut around them.

It is a fragrant softwood that provides good stability when boards are quartersawn. This affordable, abundant and lovely wood is ideal for building furniture projects.

Red Alder

Red Alder is a good low-cost substitute for cherry as it has an identical wood grain pattern.

Broad, long, clear red alder boards are easily available, and they hold stains and dyes well. It is also a lightweight wood that cuts easily and is dimensionally stable.

Red Elm

Red elm usually has a reddish-brown color with tinges of green and yellow. It is widely used to build furniture as it bends and cuts easily and is durable.

Its wood grain looks like a combination of red oak and ash without the flecks. It leaves behind a smooth and attractive surface after planing.

Aspen

Aspen can be used as an alternative for walnut or cherry. Its faint grain and creamy white color give it a uniquely beautiful look that makes it suitable for use as a primary or secondary wood in DIY projects. Aspen easily absorbs glue and paint and is easy to work on with power tools and hand tools.

White Ash

White Ash is low in density but high in durability. It can be bent easily with steam and so is ideal for building curved furniture sections like aprons and legs.

It is easy to cut and works well with all tools. Its creamy, rich white color makes it ideal for building stunning, low-cost furniture pieces.

Soft Maple

Soft maple has a lovely grain pattern that is almost the same as hard maple. It is easy to work with tools and is suitable for ebonizing.

Although mainly used as a secondary wood, it can also be used quite effectively as the main timber for constructing fine furniture.

Red Oak

Quartersawn red oak has a clean liner grain with light shimmers of ray flecks. It is a long-lasting, lovely and shiny wood that can be used in many kinds of woodworking projects.

Poplar

Poplar usually has green streaks, which woodworkers try to hide by staining. But this can leave blotches. So they hesitate to use it as primary wood.

Instead, if you finish poplar with oils and let it age naturally, then it will turn into a light golden color, and the streaks will change to darker hues of brown.

This assortment of colors can be used to create a beautiful effect if used wisely when building furniture parts.

Hickory

Hickory has lovely grain patterns that look like flames. It can be tough wood to work with hand tools, so it is best to use only power tools on hickory.

Beware of cracking as the cracks can get deeper over time. Hickory can be used as an affordable replacement for cherry or walnut when building furniture projects.

Beech

Beech has an even wood grain and is quite easy to work with. It has gentle flesh-colored hues with subtle flecks. Although it is a beautiful hardwood, it isn’t that sturdy.

Use beech for building sections of your DIY projects that don’t need to withstand any loads.

12 Essential Hand Tools For Woodworking

Every woodworker must have a quality workbench and a set of these must-have woodworking tools that will be needed repeatedly in building DIY projects.

Let us look at the most basic hand tools for woodworking that you should get familiar with.

Chisel Set

You can start with the four basic chisels of 3/4 inch, 1/2 inch, 3/ 8 inch, and 1/4 inch.

These are the chisels that will be frequently used for cleaning grooves and shaping mortises.

Later on, you can add the 2-inch and 1 1/2-inch chisel that will be used for chamfering and paring.

Block Plane

You will need a block plane for smoothing grain, leveling joints, and chamfering edges. It is also used for smoothing dovetails.

Get a plane with a flexible throat and a low-angle blade. This helps you make finer cuts and prevents the wood from tearing out.

Shoulder Plane

A shoulder plane is the best way to make fine adjustments on joints to fit them perfectly. As the blade in this plane spans the entire width of the sole, you can use it to plane tightly into any corner.

Shoulder planes are available in various widths.

Get a broad shoulder plane so that you can plane both slim shoulders and wide tenons. Its weight will keep the sole flat as you slide it forcefully to make cuts across the grain.

Bench Plane

A bench plane or smoothing plane can remove all marks from a wood surface and leave behind a glass-like finish in no time. This plane can give faster and superior results compared to sanding.

Get yourself a No. 4 size bench plane, to begin with. Sharpen your plane frequently to keep the blade razor-sharp and get the best results each time.

Spokeshave

Using a spokeshave is the fastest way to smoothen curves that are bandsawn. It is basically a hand plane with a short sole and side handles.

Spokeshaves are available with both curved and flat soles. The flat sole is better as it can be used for both flat and curved surfaces.

Card Scraper

A card scraper is the best tool for removing small tear-outs on timber boards with complex grains.

A scraper has no chance of producing a tear-out, so it is the ideal tool to remove any imperfections in the boards you use for woodworking.

Marking Gauge

A marking gauge is used to scribe a line parallel to a board’s edge that is usually used for placing cuts for dovetails, mortises, and tenons accurately.

A line that is cut into the wood is better than one drawn with a pencil as it gives an exact position for cutting with a handsaw or chisel.

Bevel Gauge

The pivoting blade of a bevel gauge can be locked into any angle, and you can trace that angle over and over again on different boards.

This makes it a very useful tool for transferring angles onto a large number of workpieces accurately and quickly.

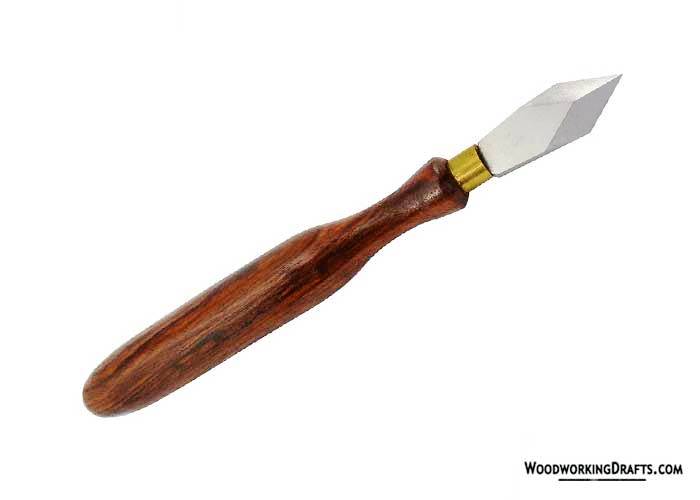

Marking Knife

You can use a chip-carving knife or a utility knife as a sharp tool for scribing lines on boards. Pick a knife with a thick blade, so it remains stiff and doesn’t bend while marking.

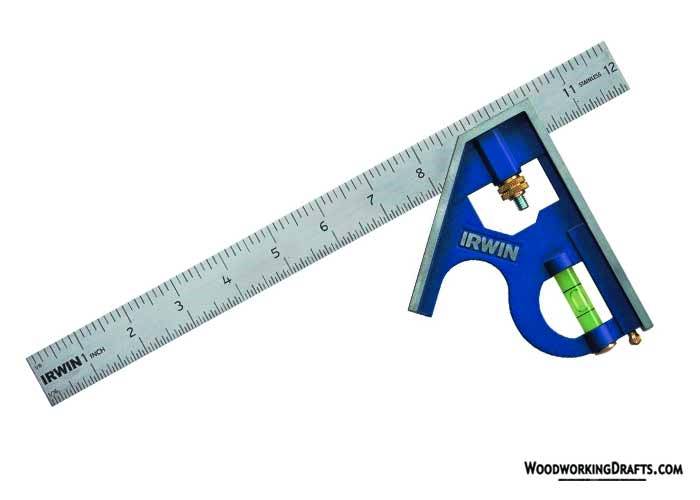

Combination Square

A combination square is used to scribe 90-degree and 45-degree angles into the wood. It is available in 6-inch and 12-inch sizes.

If you don’t do much outdoor construction work, then a 6-inch square is sufficient for your needs. The smaller size will also fit easily into tight corners.

Dovetail Saw

You can use either a pull saw or a backsaw as a dovetail saw. Dovetails are frequently used when building any kind of wood joinery. Having a sharp and durable dovetail saw will help you cut fine dovetails precisely and quickly.

Coping Saw

A coping saw is used mainly to quickly cut away waste wood between joinery sections like the pins and tails in dovetail joints.

As you can turn this tool easily around tight corners while cutting, you can clear out waste much faster with a coping saw than with a chisel.

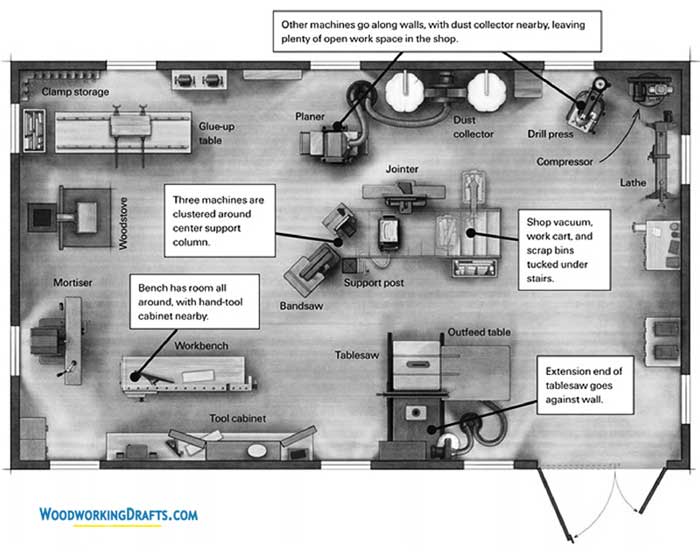

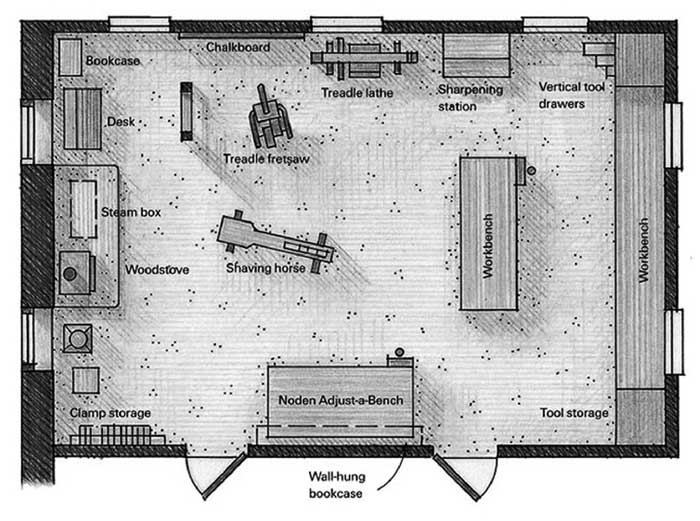

Wood Shop Layout Plans For Small, Medium & Large Spaces

The way you set up the workspace where you build your DIY projects can may a huge difference in the time, cost, and effort needed for woodworking.

Workspaces can vary a lot in size and layout. You may have a huge industrial space available for work, or you may be restricted to a tiny garage.

Shop layouts can vary a lot, but most have similar kinds of equipment. You will need a space to store the lumber, a workbench, and a table saw or router table.

Let us look at the different efficient woodshop layouts that can be set up in large, medium, and small spaces, including garage-based workspaces.

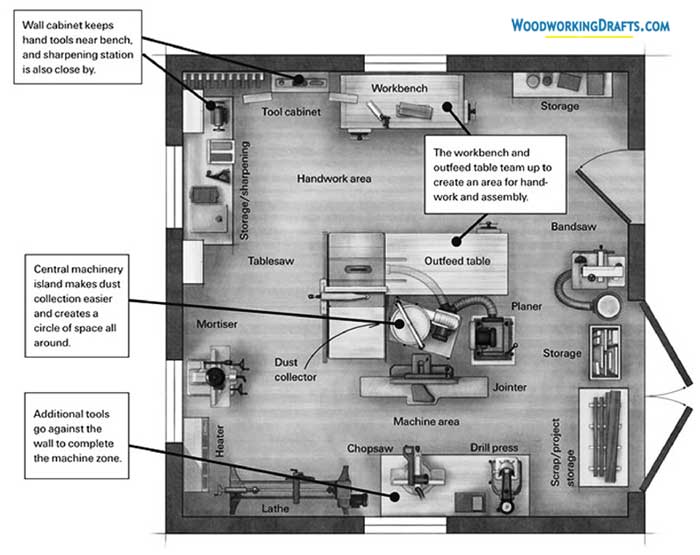

20×40 Large Sized Wood Shop Layout Plans

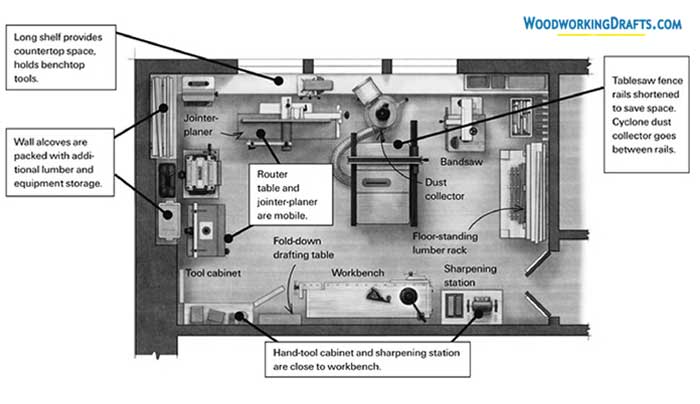

20×20 Medium Sized Shop Layout Plans

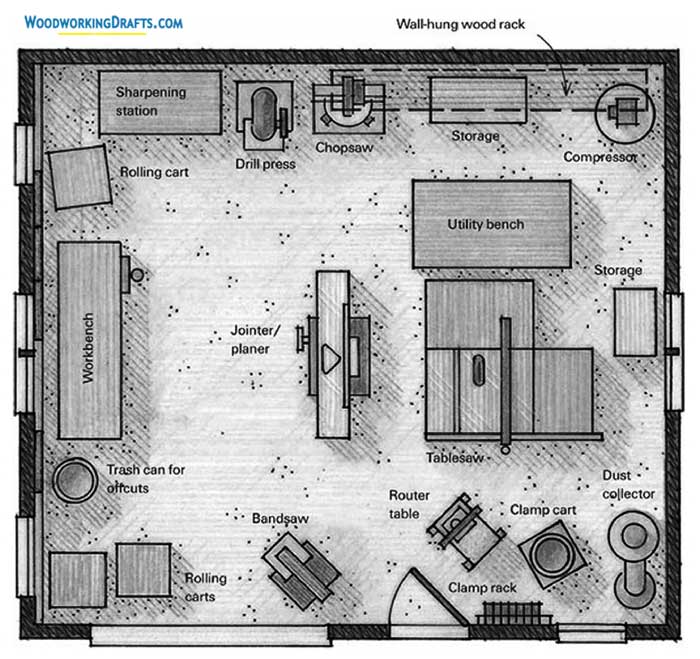

11×17 Small Sized Shop Layout Plans

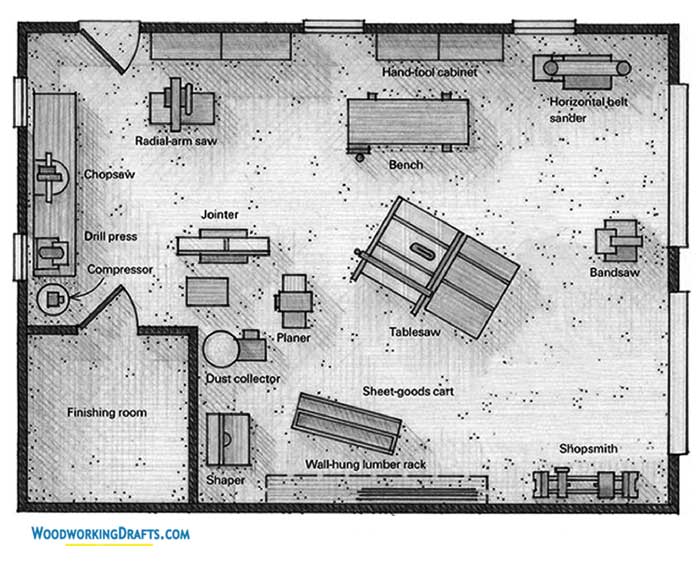

Garage Based Wood Shop Layout Plans

Frequently Used Woodworking Terms

Here are some of the common terms you will frequently come across in woodworking plans and books.

Arris

The sharp edge between angled surfaces is called arris. It is commonly beveled or rounded while completing the project.

Aperture

The space between two sections of a structure, like a gap between two legs of a table, is known as the aperture.

Buttons

Wooden fittings used to secure a tabletop with the frame are called buttons.

Break out

As wood exits from a bit, cutter or blade, sometimes it gets damaged, and the wood fibers tear out and break from the surface. This is called break out.

Carcase / Carcass

The skeletal box structure of any box-shaped furniture like a cabinet is called a carcass.

Caul

A sturdy board that is used to distribute the clamping force evenly across a wood surface when gluing veneer to a core.

Chamfer

An edge between two faces that is beveled at an angle. Usually, the angle is 45 degrees.

Countersink

A conical hole is drilled into a timber piece into which a screw is inserted. The screw should fit tightly into the hole such that the screw head should be flush with the surface of the wood.

Cross-cut

A cut was made at a 90-degree angle to the wood grain.

Double rebate

When two grooves are cut into a wooden face such that it creates a narrow tongue-like strip in between them, then these grooves are called a double rebate.

Floating panel

A wood panel that is left without gluing in a frame so that it allows shrinking and swelling of the wood as the climate changes.

Housing

A groove is cut into a piece of timber into which another piece is housed or fitted tightly.

Kerf

Kerf is the width of the cut left behind by a cutting tool on wood. A circular saw has a wide kerf, a band saw’s kerf is medium-sized, and a dovetail saw leaves a narrower kerf.

MDF

MDF is short for medium-density fiberboard. It is an engineered wood that is produced by mixing wood fibers and adhesives and bonding them together under high levels of pressure and heat.

MDF doesn’t shrink, swell or warp and is very durable.

Mortise

A mortise is a recess cut into a workpiece that will house a matching tenon from another workpiece to form a mortise and tenon joint.

Pare

The process of cutting away extra wood to create a particular shape, like when a chisel is used to carve wood at a 90-degree angle.

Peg

A tapered, tiny wooden notch that is installed inside a mortise to resist tension and fasten two timber pieces together.

Quarter-cut

When a log is cut into quarter pieces radially and every quarter is milled into boards that run at right angles to the log’s rings, this is called quarter-cutting. This creates the most dimensionally stable lumber boards.

Racking

Any side-to-side motion which tries to tear out a wooden joint is called racking stress.

Relief cut

An initial cut is created perpendicular to the cutting line while crafting a curve. This cut relieves the tension on the blades of the saw as it cuts around the curve.

Ripping

When wood is sawn in the direction of the grain, it’s called ripping or rip cutting.

Score

To scribe a line on a piece of timber by cutting gently into the surface.

Shrinkage

As the timber dries, it causes shrinkage. The changes in air moisture content as the season changes can also cause wood to expand and shrink.

Splay

An extending of a shape like how a wedged tenon is wider at the end.

Splinters

Shards of timber that poke out or detach from a timber surface when it is not smoothened.

Stile

The vertical members of any frame are called stiles.

Stock

A blank and uncut piece of timber from which a workpiece is crafted is called stock.

Template

A pattern, shape, or outline that allows the design to be precisely transferred onto craftable timber materials.

Tenon

A projection at the end of a workpiece that is crafted to snugly fit into a mortise as part of a mortise and tenon joint.

Tongue

A wooden ridge that is crafted to fit accurately into a matching groove.

Veneer

A thin layer of wood is glued to another timber material, usually for decorative purposes.

Workpiece

The lumber piece that is currently being worked on with hand tools or power tools as part of a woodworking project.