Your Guide To The Most Popular Wood Joinery Techniques

Your journey from an amateur woodworker to a master craftsman will involve learning all the different types of woodworking joints that are both strong and beautiful.

As you master each woodwork join technique, your ability to build more complex and durable projects will grow quickly.

From the most basic butt joints to the most complex secret dovetail joints, each wood joint has a specific function. Knowing the strengths and weaknesses of each joinery technique will help you become an expert woodworker.

How Strong Is A Wood Joint?

In any woodwork project, the joints secure the different pieces together.

Knowing the best way to join each piece with the others is essential for durability and stability when using DIY woodworking plans to craft any project.

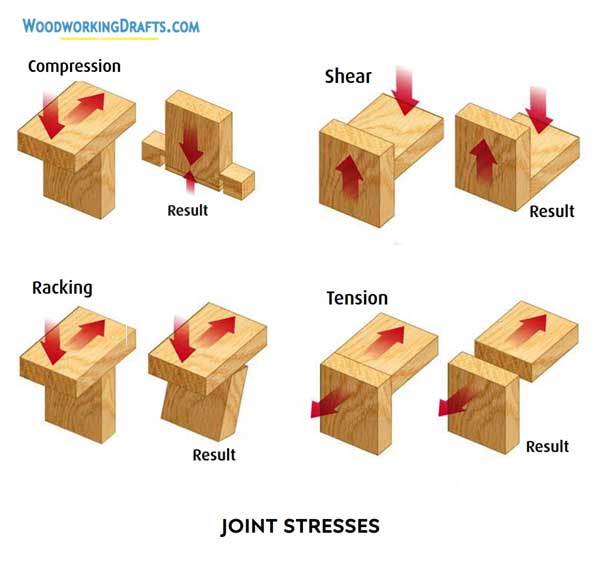

Any woodworking joint is subject to four types of stresses, compression, racking, shear, and tension.

Compression stress squashes the members of a joint together like when it is pushed down under the weight of a load.

Shear stress is caused by pressure in line with the joint. It pushes the connected members in opposite directions. This can cause a joint to come apart if it is not reinforced with a peg or a tongue and is only held by glue.

Racking stress or bending rotates the joint members around one another.

Tension stress happens when forces acting on a joint try to rip it apart like the force a drawer’s front experiences when a heavily filled drawer is pulled outwards while opening.

The different types of wood joints have unique resistance capabilities against these four individual stresses.

Let us take a look at all the best types of wood joinery as well as their strengths and weaknesses.

Butt Joints

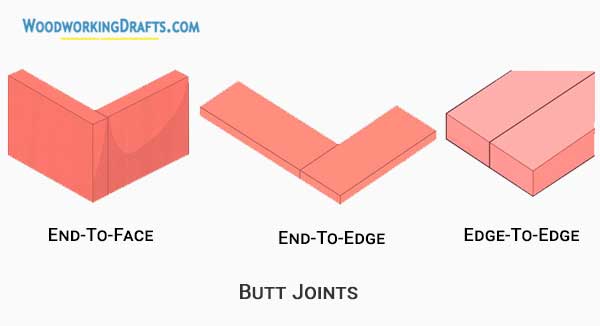

Butt joints are the most basic type of woodworking corner joints.

They consist of two pieces of timber (best wood types for woodworking) simply butted together at a right angle or along the edges.

It is a weak joint but can be reinforced with dowels or loose tenons.

Basic Butt Joint

The basic butt joint consists of two pieces of timber connected to each other at right angles, as in the case of an edge-to-face or end-to-face butt joint. The boards are usually fastened using glue or nails.

Edge-to-edge joints are also classified as butt joints and are used to connect narrow boards together to create wider pieces of straight lumber.

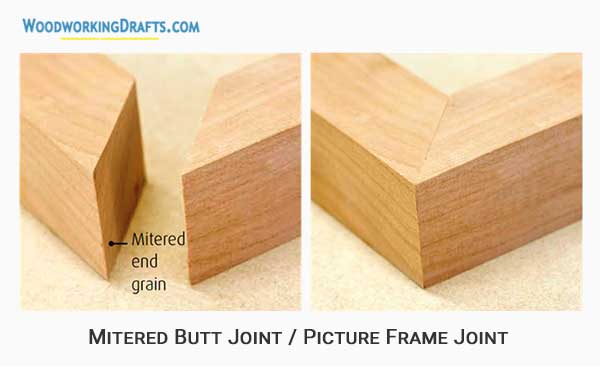

Mitered Butt Joint / Picture-Frame Joint

The mitered butt joint secures two pieces of lumber at an angle of 45 degrees without exposing any end grain. This joint is more beautiful than the basic butt joint, but it still has the same limitations, so it’s a weak joint. Biscuits or dowels (best woodworking tools) can be used to reinforce this joint and make it stronger.

This joint is usually used to construct picture frames and tabletops. Gluing the two mitered pieces may be a bit tricky as they could slide off. Hence the joint members need to be held down during the glue drying period.

Lap Joints

A lap joint is a joint in which the two timber pieces being connected overlap each other.

They are a bit stronger than butt joints and require more effort and precision in their construction.

Full Lap Joint

A full lap joint is the most basic way of connecting two wooden members. You just put one member on top of the other and fasten them at the joint with nails or other fasteners.

It is a weak joint and quite ugly to look at. Any tension can easily rip apart the joint. This joint is rarely employed other than in construction work for temporary bracing.

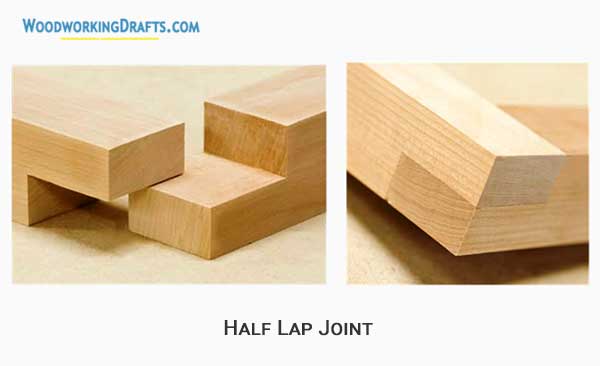

Half Lap Joint

A half lap joint is similar to the full lap with one key difference that half the wood is removed from each connecting member along its thickness.

So if two timber boards of one-inch thickness are being joined together, then half an inch of wood would be removed from the end of the boards being connected. Hence, the final joint will have the same one-inch thickness after the two halves are fastened together.

As the area available for gluing is larger, this joint is stronger than butt joints.

This joint is typically used in picture frames, cabinet making, and less intricate woodworking projects. It is relatively simple to make and provides medium durability.

Mitered Half Lap Joint

When you create a half lap joint by mitering both ends of the half-lapped timber boards at a 45-degree angle, it produces a mitered half lap joint.

This joint has more gluing area than the simple half-lap joint because of the mitered shoulder, so it is really strong. The miter also gives this joint a beautiful appearance.

The mitered half lap joint requires precision and skill because of the complex cut. It is not an easy joint to make. It is commonly used in picture frames, woodworking, and cabinetry.

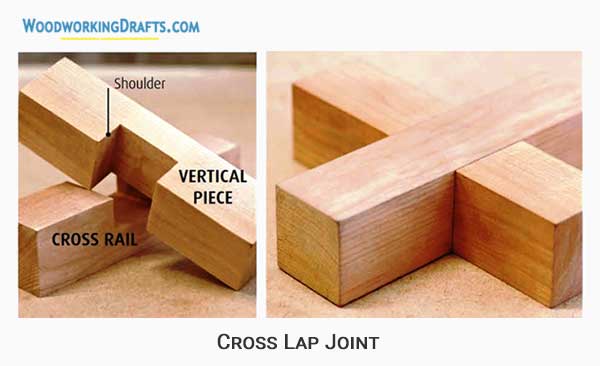

Cross Lap Joint

A cross lap joint or a crosshalved lap joint is one of the strongest joints in woodworking.

Similar to the basic half-lap joint, timber is removed from both the boards, but here it is removed in the center of the boards instead of the ends. This results in two shoulders on each board and a very large gluing area.

This joint is much stronger than the half-lap joint and resists racking stress effectively.

Cross lap joints are used in building doors, furniture, and woodworking.

Dovetail Half Lap Joint

The dovetail half-lap joint looks similar to the cross-lap joint. It is a joint between the end of one member and the center of another member. The key difference is that instead of removing wood in a square shape, it is cut out in a V shape known as a dovetail.

This dovetail lapping makes the joint both lovely and sturdy. It resists both pullout and racking. The dovetail half-lap joint is the strongest of all the lap joints.

It is commonly used for building drawer rails and different kinds of carcasses for cabinets.

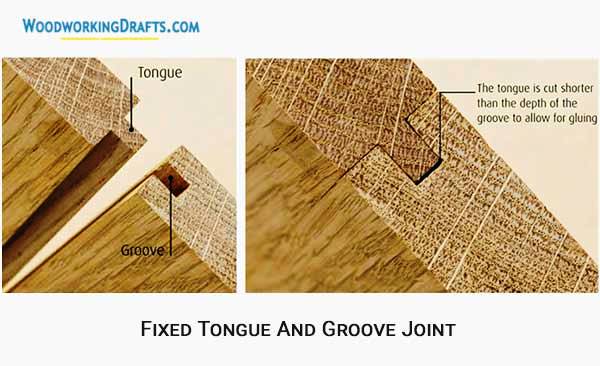

Fixed Tongue And Groove Joint

The fixed tongue and groove joint is a reinforced form of the edge-to-edge butt joint. It consists of a groove cut along the edge of one board that fits with a tongue or ridge cut into the edge of the other board.

The tongue’s depth is kept slightly less than the depth of the groove to allow for glue and space for expansion and contraction of wood.

The increased gluing area makes this a very strong edge-to-edge joint. It is a versatile joint that has many different applications. It is usually used in parquetry, paneling, floorboards, backs of dressers, and bookcases.

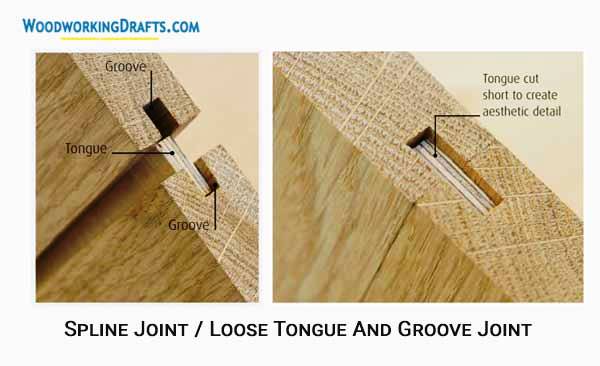

Spline Joint / Loose Tongue And Groove Joint

A woodworking spline joint is created by cutting matching grooves into the edges of two boards and then inserting a wooden spline that acts like a “loose” tongue into these grooves and gluing them together.

A contrasting colored wood can be used for the tongue or spline to create a decorative effect.

This joint is often used as an alternative for the fixed tongue and groove joint as it is faster to build. The spline joint is frequently used to create larger panels from narrow timber boards.

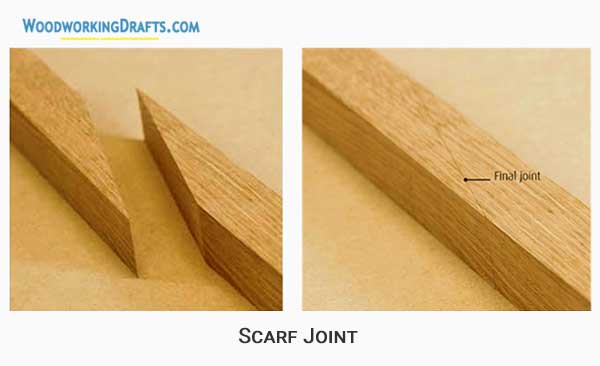

Scarf Joint

When two timber pieces are connected lengthwise by cutting their ends at 45-degree angles and fastening with each other, it creates a scarf joint.

Scarf joints are commonly used in carpentry to extend the length of skirting boards, architraves, and dado rails. It is also used in building wooden guitars to connect the head of the guitar with the neck.

If the joint will take any load, then it must be reinforced with a biscuit or tongue connector.

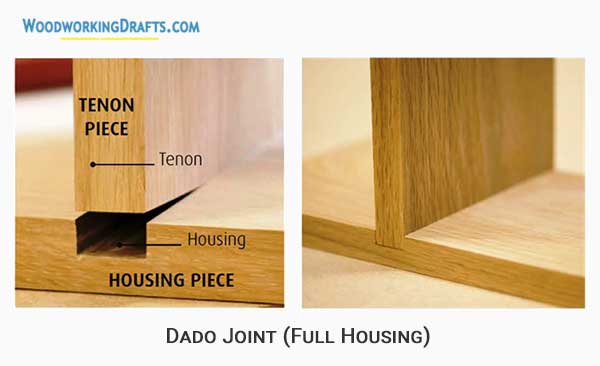

Dado / Housing Joints

A dado or a housing joint is formed when one end of a board is fitted into a square groove cut into the middle of another board.

Dado Full Housing Joint

In the basic dado joint, also known as a full housing joint, the end grain of one timber board acts like a tenon and fits into a groove or housing cut into another board at a right angle.

This is a simple joint that is usually used for building carcass furniture like drawers or desks, sideboard plinths, and bookcase shelves.

Although this joint can effectively resist a downward compression caused by a load, it cannot withstand any tension sideways.

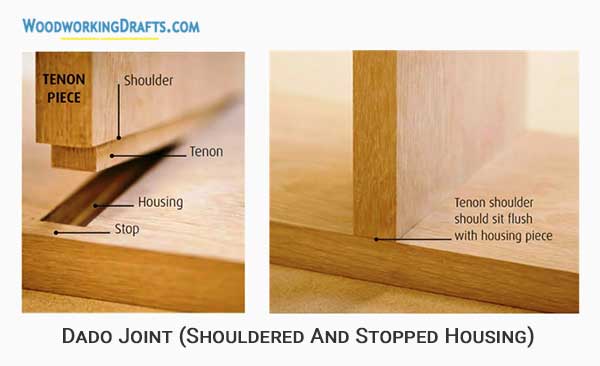

Dado Shouldered And Stopped Housing joint

In the shouldered and stopped housing joint, a shoulder is cut into the piece of the timber that acts like a tenon, and a stop is cut into the board which holds the housing.

This effectively hides the joint, thus making it ideal for use in desks, carcasses, box dividers, drawer divisions, or any use where looks are important.

The extra area of contact provided by the shoulder and stop makes this joint much stronger than the basic dado joint.

Mortise and Tenon Joints

When built correctly, mortise and tenon joints are one of the strongest joints in woodworking. It has been in use for thousands of years and is considered one of the oldest and most popular types of wood joinery.

Basic Mortise and Tenon Joint

The basic mortise and tenon joint is formed by cutting a pocket or mortise into one piece of wood and a matching projection known as the tenon into the other piece of wood.

The tenon fits into the mortise, usually at a right angle. The tenon’s shoulders sit snugly against the perimeter of the mortise and prevent the tenon from slipping out of the mortise.

It is a versatile joint that has a wide range of applications in building furniture like dressers, cabinets, chests, and various other woodwork projects.

A properly secured mortise and tenon joint is very strong because it can resist compression, racking, shear, and tension.

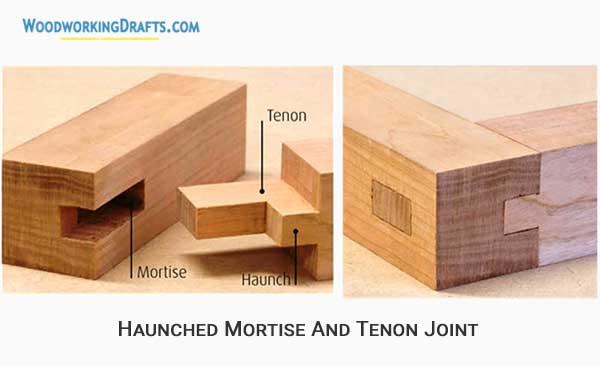

Haunched Mortise and Tenon Joint

The haunched mortise and tenon joint is a modification of the basic joint that mainly developed from frame-and-panel carcassing.

In this version of the joint, the haunch fills and reinforces the end of the groove. It allows the tenon to be extra thick near the shoulder while maintaining the same depth for the mortise.

This increases the gluing area for the joint and makes it sturdier.

Secret Haunched Mortise and Tenon joint

Whenever an extra durable haunch is required and the joint needs to be hidden from view, then a secret haunched mortise and tenon joint is created.

It is commonly used in furniture construction for making cabinet door tops, chairs, and drawers.

The additional gluing area makes it a really robust joint, and as it is hidden, it also looks aesthetic.

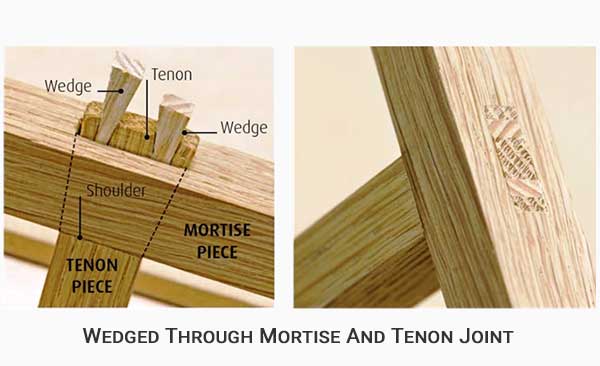

Wedged Through Mortise and Tenon Joint

The wedged through mortise and tenon joint is an extremely durable joint that can’t be pulled back once it is set in place. This makes it an ideal joint for chests of drawers, chair legs, and any carcass that requires reinforcement.

Contrasting colored wood can be used for the wedge pieces to create a decorative effect.

The tight fit of the tenon inside the mortise makes this a very durable and non-removable joint.

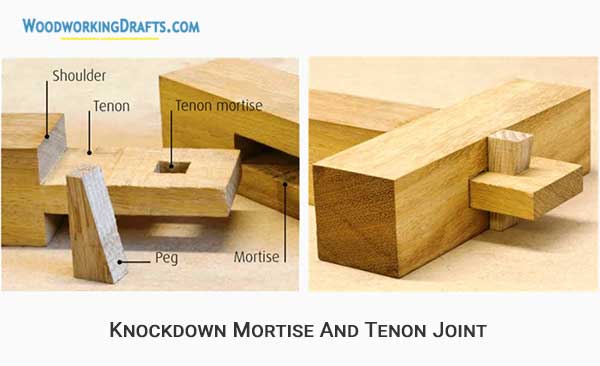

Knockdown Mortise and Tenon Joint

The knockdown mortise and tenon joint is frequently found in the furniture built during the Arts and Crafts movement and in Asian furniture.

The removable peg inserted in the tenon allows this joint to be easily taken apart and reassembled when needed.

This makes it a suitable joint for building large items like beds or bookcases that may need to be taken apart into smaller pieces during transportation.

Draw-Bore Mortise and Tenon Joint

The draw-bore tenon is one of the most ancient forms of mortise and tenon joints that have been in use since medieval times.

As this joint was designed before durable wood glues became available, it is able to create a tight joint even when no glue is applied.

The draw-bore mortise and tenon joint is put together dry and then reinforced with the doweling peg that pulls the shoulders snugly to the bore.

This is a sturdy joint that doesn’t need gluing.

Floating Tenon Joint

The floating tenon joint was the predecessor of modern connectors like the domino and biscuit joint. It is also known as a slip or loose tenon joint.

As there are no shoulder lines to craft and both connecting members are of the same size, it can be constructed much faster than the standard mortise-and-tenon joint while still providing the same strength as the standard joint.

Domino Joint

A domino joint is a modern form of the basic mortise and tenon joint. The domino mortises are cut with a specially designed domino jointer that comes with cutters in a wide range of sizes.

The depth of the cut can be adjusted by changing the depth setting on the jointer.

Different settings of the domino jointer allow the tenon or domino to be created in varying widths, lengths, grain orientations, and in wooden members of varying thicknesses.

This makes it easy to create strong domino joints in any situation where a standard mortise and tenon joint would have been employed. And since the cut is made by a special machine, a large number of joints can be created very quickly and with high precision.

The domino joint is very versatile and can be used in a wide variety of projects like doors, carcass construction, and chairs.

Bridle Joints

A bridle joint in woodworking is essentially an open mortise and tenon joint. In this joint, both the tenon and mortise members are cut to the full width of the wooden pieces.

Most forms of bridle joints don’t use any mechanical fasteners. But because of their large gluing surface and the strength of modern wood glues, they can create very sturdy joints.

Corner Bridle joint / Slip Joint

In the corner bridle joint, two wooden members are joined at their ends, thus creating a corner joint. It is also known as a slip joint and is the most commonly used form of the bridle joint.

This joint is usually used to house a member in the upright position. For example, the legs of a chair can be attached to its seat using a triple corner bridle joint.

This joint strongly resists compression but only moderately resists racking as it depends on glue for its strength. It can be reinforced with mechanical fasteners like nails or dowels.

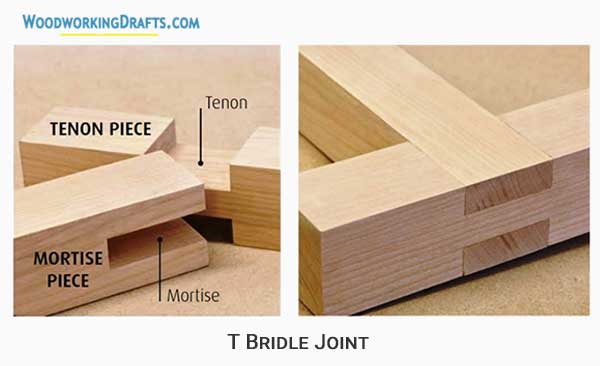

T-bridle Joint

A T-bridle joint or an open-slot mortise and tenon joint is very sturdy even without glue. In this joint, the corner of one wooden piece is connected with the middle of another piece to create a T shape.

As the tenon is fully straddled by the mortise, this joint provides strong resistance to racking. It is usually used in carcass framing or while connecting a table leg.

Box Joint / Finger Joint / Comb Joint

A box joint, also known as a finger joint or comb joint, is a less complex version of the through-dovetail joint.

This joint basically consists of a set of interlocking and complementary square profiles cut into the wooden members. Once the two members are put together, the joint looks like the interlocking fingers of two hands.

This joint is usually employed for building carcasses, box corners, and long pieces of solid boards for trims and moldings. Sometimes different colored wooden members are used to enhance the aesthetic appeal of the joint.

Because of its large gluing area, it can create a very strong joint. It also takes lesser time and effort to construct compared to crafting a group of dovetails.

Dovetail Joints

Dovetail joints are a favorite classic of any truly traditional woodworker. They consist of complementary pins and tails cut into the two connecting members that interlock with each other.

When glued together, it forms a durable, long-lasting, and tight joint that strongly resists being pulled apart even without any mechanical fasteners.

Dovetail joints are one of the strongest woodworking joints that have been in use for centuries. They can be easily found in antique desk drawers and many other quality pieces of classic furniture.

The only limitation of this joint is that it can be a bit complex and time-consuming to build.

Through Dovetail Joint

The through-dovetail joint is the simplest and most popular among all the dovetail joints.

In this joint, two wooden members are connected at the ends with each other by a finger-like pattern of dovetails that interlock with each other.

This joint resists tension very well, and so it forms a sturdy corner joint. It is one of the oldest and strongest joints in woodworking.

Through-dovetail joints are frequently used as corner joints for constructing boxes and carcasses because of their beauty and sturdiness.

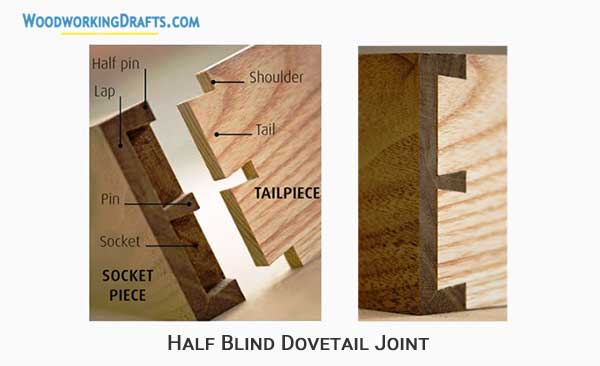

Half-Blind Dovetail Joint

A half-blind dovetail joint is used when you want to conceal the joint from view on the front side. Here, instead of cutting the dovetails right through the wooden members, the tails are placed into sockets cut into the board ends.

This is a popular joint used for fastening the front end of a drawer with the side pieces. It is also used in carcass construction.

Just like the basic dovetail, the half-blind dovetail joint is good at resisting pullout caused by tension.

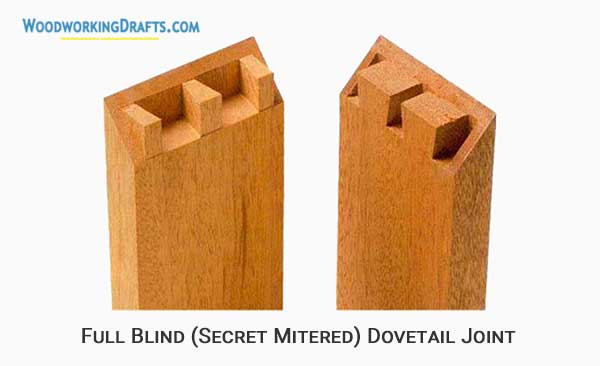

Full-Blind (Secret Mitered) Dovetail

The full blind dovetail joint, also known as the secret mitered dovetail joint, is one of the most intricate types of wood joints.

It provides the same sturdiness as a through dovetail but is completed hidden from both inside and outside view. The outer edges of the wooden members meet at a 45-degree angle and conceal the dovetails within them.

It is usually only used in the best quality pieces of finest high-end furniture.

Sliding Dovetail Joint / Dado Dovetail Housing Joint

A sliding dovetail joint connects two boards at right angles, similar to a dado joint. It combines the strengths of a dado or housing joint with a dovetail joint.

The tail end of the dado below the shoulder is cut in the shape of a dovetail. The dovetailed wooden member can then be slid into the socket of the other member and locked into place even without glue. The dovetailed end makes this stronger than a traditional dado joint.

The rear end of the socket in this joint is usually made narrower than the front end so that the fit becomes tighter as you slide the dovetail inside. This makes the final position of the dovetail fit very snugly.

This joint resists both racking and pullout, which makes it the strongest type of dado joint. It can also be used as a knockdown joint that can be put together and taken apart when needed.

This joint is commonly used in bed frames, carver chairs, open bookshelves, and other types of carcass construction where rigidity is very vital. It is also used when more common joints may not be practically feasible, such as for making drawer dividers and breadboard ends.

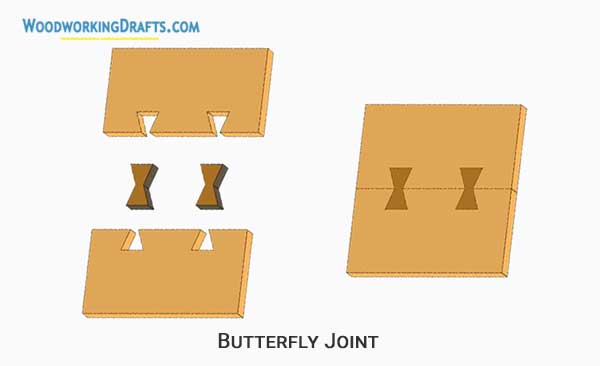

Butterfly Joint / Dovetail Key Joint

A butterfly joint is mainly used for aesthetic purposes and to strengthen and hide splits and cracks in lumber and furniture pieces.

The joint looks like two dovetails connected at the narrow ends forming a bow tie-shaped structure. That is why this joint is also known as a dovetail key joint or a bow tie joint.

This joint can also be used to strengthen the weakness caused by a knothole in the timber.

Sometimes the wood used to craft the dovetail keys or butterfly has a contrasting color from the wood into which the groove is cut. This enhances the beauty of the final joint.

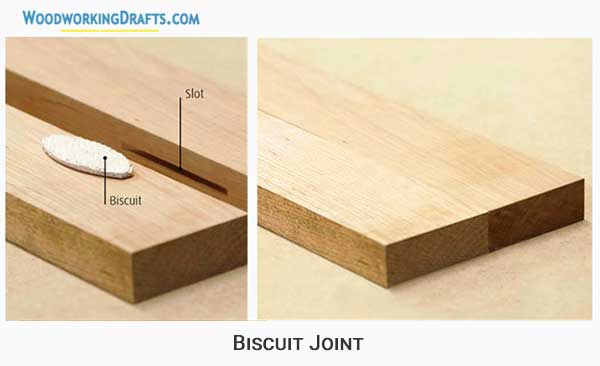

Biscuit Joint

A biscuit joint is a modern technique of wood joinery which is similar to the loose tenon joint. Two curved slots are cut into the two joining wooden members, and a biscuit is inserted into them and glued into place.

The biscuits, which from the loose tenons, are usually oval in shape and come in different widths and a standard thickness.

The slots into which the biscuit is inserted are created using a specialized biscuit joiner. The joiner comes with various fences that allow the slots to be cut at different angles.

This joint can be created very quickly and easily because slots can be cut quickly with the joiner. As the biscuit is long grain, it forms a much stronger joint than dowels.

Biscuit joints are frequently used to replace mortise and tenon joints that can be quite time-consuming to craft. Their only disadvantage comes from the shallow size of the biscuits, because of which they may not be useful in a situation where a deep tenon is needed, like in some forms of frame building.

This joint is frequently used for connecting sheet timber material like MDF, particleboard, or plywood. It is also commonly used to attach frames to carcasses.

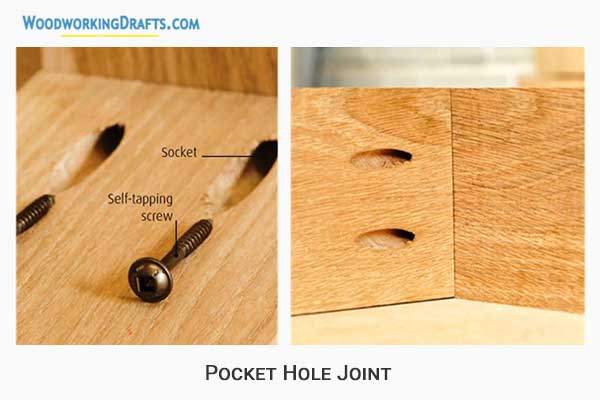

Pocket Hole Joint

Pocket hole joints are built using a commercial method known as the Kreg system. This joint is essentially a variation of the butt joint with a pocket hole drilled into the wood.

Pocket holes are created using the specialized Kreg jig, which has settings to adjust for different timber sizes, depths, and alignments. The joint requires drilling a clearance hole and a pilot hole each time.

Although this is a strong joint, it does not look pretty. So woodworkers usually only use it in sections where the joint would not be visible from the outside.

The pocket hole joint is very useful when the space available for crafting a joint is limited. The joint can be further reinforced with glue.

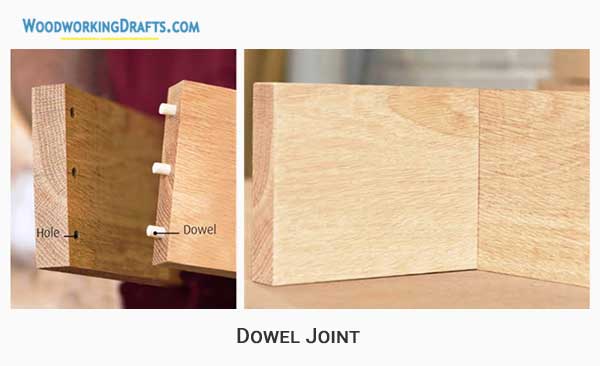

Dowel Joint

Dowels are cylindrical rods made from wood, metal, or plastic that are used to reinforce joints.

Dowels can be used to reinforce corner joints like butt joints that are otherwise not that sturdy. Multiple dowels are positioned in a line to further increase contact and gluing area.

After the introduction of pocket hole joinery, dowels have become less popular since they are time-consuming to create.

However, glued wooden dowels provide much greater strength to joints compared to nails or screws.

Rabbet Joint / Rebate Joint

A rabbet is essentially a dado that is cut along the edge of a timber piece. In the basic rabbet joint, the timber is cut almost the entire thickness of one of the wooden members to form a groove. The other member is fitted into this groove at a right angle.

A double rabbet joint creates a groove in both the joining timber pieces. This makes it sturdier than the basic rabbet. It also resists racking stress better.

In a locking rabbet joint, a tongue and groove are cut into the ends of each of the connecting pieces. This results in a very strong joint because of the larger gluing area.

Rabbet joints are frequently employed in making bookcases, window frames, door casings, and kitchen cabinets.

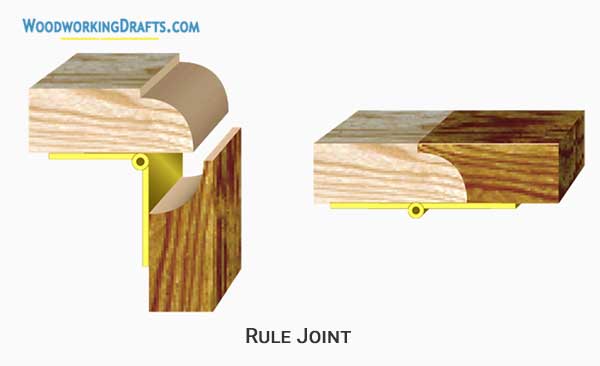

Rule Joint

Rule joints are mainly used for constructing drop-leaf tables. The joint is made up of a cove at the bottom and a fillet at the top connected by a hinge. The joint got its name because it resembles the knuckle joint on vintage rulers.

When the leaf of the table is pulled up, the edges of the cove support the leaf and remove stress from the hinges. When the leaf is down, the end of the cove hides the hinges from view.

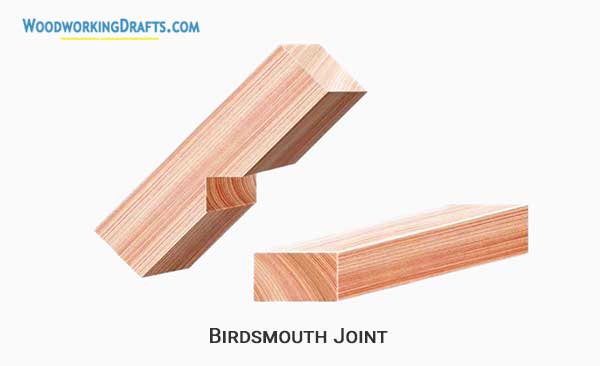

Birdsmouth Joint

Birdsmouth joints are primarily used in roof construction. The roof rafters are usually connected to the wall top plates using this joint.

When built properly, birdsmouth joints are very sturdy at resisting compression. The weight of the roof gets evenly distributed on the wall plates and down to the foundation.

This joint resists the pull of gravity on the roof members and holds up the weight of the roof effectively.

Castle Joint

A castle joint combines a bridle joint and a half lap cross joint to create an interlocking joint that connects in three ways. This combination makes it one of the strongest joints in woodworking.

It may look complicated but is simple to make. It consists of a castle cut into the end of one timber piece. And two timber members with half-lap joints that interlock with each other over the castle piece.

It is usually used at the corners of tables, beds, and any part of furniture where both strength and beauty are needed.

As you practice building each of these types of woodworking joints as part of various projects, you will become more and more skilled at choosing and crafting the right wood joinery techniques. Over time the speed and precision with which you will construct wood joints will improve greatly.